Gold leaf application remains one of the most exacting decorative techniques in contemporary design, demanding both technical precision and material knowledge. Modenese Furniture, a premier Italian furniture firm, continues to employ traditional 24-karat gold gilding methods in its bespoke creations, demonstrating how centuries-old techniques integrate with modern luxury manufacturing. The craft separates into two distinct methodologies: water gilding and oil gilding, each producing fundamentally different results and suited to specific applications.

Physical Properties of Gold: What Makes Leafing Possible

Gold’s unique atomic structure enables it to form sheets measuring 0.0001 millimeters thick. According to the U.S. Geological Survey, pure gold possesses the highest malleability and ductility of any metal, with a specific gravity of 19.3. This density allows a single troy ounce to be hammered into a sheet covering approximately 300 square feet. The metal’s face-centered cubic crystal lattice structure permits extensive deformation without fracturing, enabling goldbeaters to reduce thickness while maintaining sheet integrity.

Pure 24-karat gold remains chemically inert and never tarnishes, but its softness requires alloying for practical applications. Standard gilding leaf contains 23 to 23.75 karats, incorporating minute quantities of silver or copper. These additions increase hardness while maintaining corrosion resistance. The Smithsonian’s National Museum of Asian Art documents that historical gold leaf production dates to 3000 BCE, with Egyptian artisans achieving thicknesses of approximately 1 micrometer through manual beating techniques that remained essentially unchanged for millennia.

Contemporary Gold Leaf Specifications

| Specification | Standard Measurement | Technical Detail |

|---|---|---|

| Thickness | 0.1 to 0.125 micrometers | Approximately 0.000005 inches; 250,000 sheets stack to 1 inch |

| Book Format | 25 leaves per book | Each leaf measures 3.25 inches square |

| Coverage | 39.5 square feet per pack | 500 leaves (20 books) without overlap |

| Weight | 1.25 grams per book (standard) | Double gold: 1.4-2.5 grams; Russian double: 2.5 grams |

| Atomic Layers | Approximately 490 atoms thick | Based on gold atomic radius of 174 picometers |

Karat Variations and Color Properties

| Karat | Gold Content | Alloying Metals | Resulting Color | Oxidation Risk |

|---|---|---|---|---|

| 24K | 99.9% | None | Deep yellow | Zero |

| 23.75K | 98.5% | Copper/Silver trace | Rich yellow | Minimal (30+ year exterior durability) |

| 23K | 96% | Copper/Silver | Warm yellow | Low (25+ year exterior durability) |

| 22K | 92% | Copper (red gold) or Silver (pale gold) | Variable: red-yellow to pale yellow | Moderate (interior use recommended) |

| 12K | 50% | Silver (white gold) or Copper (red gold) | Silver-white or reddish | High (requires sealing) |

Water Gilding: The Traditional Burnishable Method

Water gilding produces the highest-quality finish achievable in gold leaf application, characterized by its ability to burnish to a mirror-like surface. The Getty Conservation Institute documents this as the most technically demanding gilding method, requiring precise control over multiple preparation layers.

Substrate Preparation Sequence

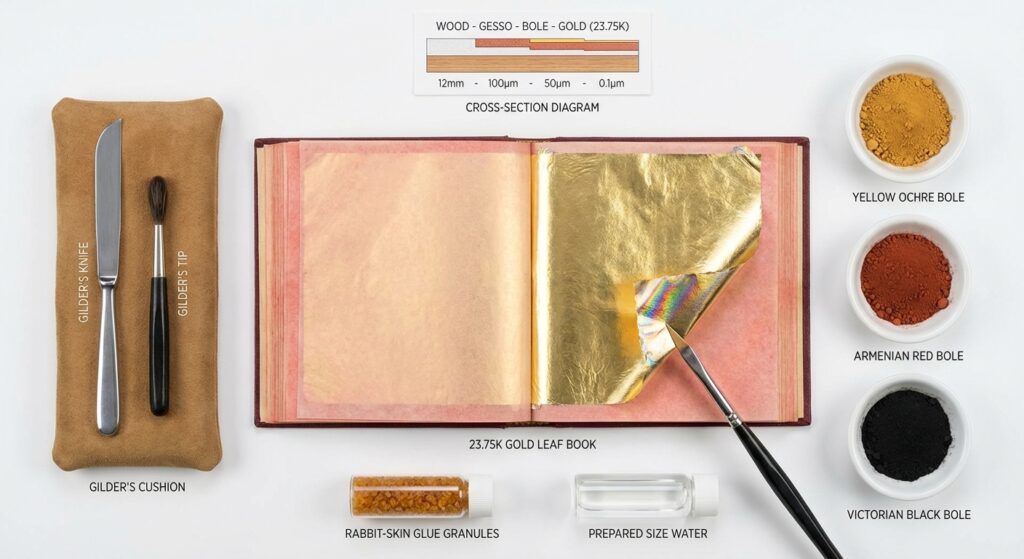

Water gilding demands a porous, sealed wooden substrate. The process begins with sizing: hot rabbit-skin glue, at a 1:10 glue-to-water volume ratio, is applied to raise and seal the wood grain. This prevents the subsequent gesso layers from being absorbed into the wood structure. Hardwoods like mahogany or walnut require minimal grain filling, while softwoods such as pine demand additional preparation, including knot sealing with shellac to prevent resin bleeding.

Gesso application follows sizing. Northern European practice employs calcium carbonate (chalk) bound with rabbit-skin glue, applied in 8 to 40 successive layers depending on whether surface carving is intended. Italian Renaissance methods historically used a two-stage system: gesso grosso (coarse gesso made from calcium sulfate and parchment size) for initial filling, followed by gesso sottile (slaked plaster of Paris in parchment size) for the final smooth surface. Each gesso layer must be applied when the previous layer reaches “matte dry” status – still containing residual moisture but not visibly wet – to prevent bubble formation from temperature differentials.

Bole Composition and Application

Bole serves multiple technical functions beyond color provision. The clay consists of microscopic flat platelets that slide across each other under burnisher pressure, enabling the polished finish characteristic of water gilding. Armenian bole, historically prized for superior burnishing qualities, contains a specific combination of aluminum silicates and iron oxides that optimize this sliding behavior.

Yellow bole is applied first over the entire gessoed surface in 2-3 layers, establishing color compatibility with gold and reducing moisture absorption rates. Red bole follows on raised areas intended for burnishing, typically requiring 1-2 additional layers. Victorian gilders introduced black bole containing graphite on isolated highlights, achieving the highest possible burnish through the graphite’s natural lubricating properties. According to conservation research from the University of Delaware, bole layer thickness directly correlates with burnishing success, with optimal depths ranging from 0.05 to 0.15 millimeters.

Size, Water Chemistry, and Gold Adhesion

Size water activates the protein glue within the bole layer, creating a wet surface for gold adhesion. The standard formulation combines 1 teaspoon of rabbit-skin glue with 0.5 pint of water and 1 teaspoon of alcohol. The alcohol serves as a surfactant, reducing water’s surface tension from 72 dynes/cm to approximately 25 dynes/cm, preventing beading on the bole surface. Alternative formulations include gin (preferred in English practice for its controlled evaporation rate) or distilled water with glair (beaten egg white). Water must wet the bole surface for 20-40 seconds before gold application; premature application results in incomplete adhesion, while delayed application leaves insufficient moisture for bonding.

Burnishing Variables and Surface Compression

| Variable | Specification | Impact on Result |

|---|---|---|

| Burnishing Tool | Polished agate (Mohs hardness 7) | Compresses gold into bole without scratching |

| Optimal Timing | 15 minutes to 24 hours post-gilding | Substrate moisture content: 12-18% |

| Applied Pressure | 200-500 grams per square centimeter | Compresses bole and gold together to 0.08 micrometers |

| Stroke Direction | Unidirectional parallel strokes | Prevents visible burnishing marks |

| Humidity Range | 45-65% relative humidity | Maintains substrate flexibility for compression |

Oil Gilding: Exterior and Non-Porous Applications

Oil gilding employs oil-based adhesives (mordants) rather than water-activated protein glues, enabling application on non-porous surfaces, including metal, glass, sealed stone, and exterior architectural elements. The technique produces a permanently matte finish without burnishing capability, but offers superior weather resistance and substrate versatility.

Mordant Chemistry and Drying Mechanisms

Traditional gold size consists of linseed oil polymerized through oxidative cross-linking. The oil contains linoleic and linolenic fatty acids with multiple carbon-carbon double bonds. When exposed to atmospheric oxygen, free-radical autoxidation forms peroxide bridges between molecules, creating a solid, tacky film. Metallic driers (cobalt, manganese, or zirconium compounds) catalyze this process, reducing drying time from weeks to hours.

Modern oil sizes are classified by nominal drying times, though actual working windows vary significantly with temperature, humidity, and substrate porosity. Japan gold size reaches tack in 30-45 minutes, but provides only 10-15 minutes of working time. Twelve-hour size typically requires 18-24 hours to reach optimal tack but allows 4-5 hours of gilding time. The extended window accommodates large-scale architectural applications where maintaining consistent adhesion across expansive surfaces is essential.

Size Tack Testing and Application Parameters

Optimal gilding occurs when the size reaches “touch-dry” status: a rubber-like consistency that resists fingerprint marking but produces a characteristic squeak when lightly rubbed. Under-tack size appears wet and mobile, causing the gold to float or wrinkle as the mordant completes polymerization beneath the leaf. Over-tack size has progressed too far during the curing cycle, resulting in insufficient adhesion and patchy gold coverage. The working tack window typically spans 15-20% of the total cure time; a twelve-hour size reaching tack at 18 hours provides approximately 4 hours of optimal working time before over-tacification.

Oil Gilding Substrate Requirements

| Substrate Type | Required Preparation | Primer Coats | Size Application |

|---|---|---|---|

| Sealed Gesso | 2-3 coats shellac + 4-6 coats oil-based eggshell paint | Yellow ochre or chrome yellow base | Single thin coat brushed out thoroughly |

| Bare Hardwood | Shellac sealer to prevent tannin bleed | Oil-based yellow undercoat (2-4 layers) | Applied directly to sealed, abraded surface |

| Plaster/Stone | Multiple rabbit-skin size coats to reduce porosity | Yellow oil-based primer (3-5 layers) | Size must dry slower; use 16-24 hour formulation |

| Metal (Steel/Iron) | Surface degreasing + rust-inhibiting primer | Alkyd-based yellow enamel (2-3 coats) | Size adheres to cured enamel surface |

| Glass | Solvent cleaning to remove oils | None (gilding applied to reverse surface) | 2-3 coats of shellac + 4-6 coats of oil-based eggshell paint |

Comparative Analysis: Water vs. Oil Gilding

Process Duration and Labor Requirements

Water gilding typically requires 5-10 days from bare wood to finished surface: 1 day for sizing and silk application, 1 day for gesso layering (8-12 coats applied sequentially), 1 day for gesso curing and sanding, 1 day for bole application (3-5 layers), and 1-2 days for gilding and burnishing after the bole has properly cured. Additional time is required for gesso recutting (in the white) on decorative pieces, potentially extending the process to 3-4 weeks for elaborate carved frames.

Oil gilding condenses the timeline significantly: 2-3 days for substrate sealing and paint layering, 1-2 days for size application and tack development, and several hours for gold application. However, the oil size requires 1-4 weeks of complete curing before the gilded surface can be handled or finished, depending on the size formulation and environmental conditions.

Technical Capabilities and Limitations

| Characteristic | Water Gilding | Oil Gilding |

|---|---|---|

| Burnishing Capability | Full mirror-like polish achievable through agate compression | None; permanently matte finish only |

| Substrate Requirements | Porous materials only: wood, unsealed plaster, stone | Any substrate: metal, glass, sealed surfaces, exterior locations |

| Weather Resistance | Interior use only; water-soluble preparation degrades outdoors | Excellent; 30+ year durability with 23K+ gold on exteriors |

| Gold Thickness Required | Standard single weight (1.25g/1000 leaves) sufficient | Double weight (2.5g/1000 leaves) recommended for exteriors |

| Repair Difficulty | Moderate; can re-wet bole and apply new leaf to blend seamlessly | High; size stains visible; repairs show distinct boundaries |

| Visual Depth | Superior; burnished areas create high contrast with matte zones | Good but uniform; no variation in reflectivity across surface |

| Application Window | Narrow; size water activates bole for 30-60 seconds maximum | Extended; 12-hour size provides 4-5 hour working period |

| Material Cost per Square Foot | $45-75 (includes gesso, bole, glue, gold) | Standard single weight (1.25g/1000 leaves) is sufficient |

Material Science: Why Authentic Gold Leaf Remains Superior

Imitation gold leaf (composition leaf or Dutch metal) consists of copper-zinc alloys beaten to similar thicknesses as genuine gold. While initially producing a convincing yellow metallic appearance, the material oxidizes rapidly when exposed to air, moisture, or sulfur compounds. Copper oxidation produces green patinas (copper carbonate) or black tarnish (copper sulfide), degrading the surface within months to years, depending on environmental conditions. Even when sealed with protective coatings, microscopic coating failures permit oxidation to begin, progressively destroying the metallic appearance.

Genuine gold’s chemical inertness ensures permanent stability. The USGS Mineral Commodity Profile confirms that gold does not react with oxygen, water, or most acids under normal conditions, maintaining its reflective properties indefinitely. Archaeological excavations have recovered 5,000-year-old gilded artifacts with gold leaf remaining bright and intact despite millennia of burial. This permanence justifies gold’s premium cost for high-value applications where longevity is essential.

Optical Properties and Light Interaction

Gold’s electronic band structure produces its characteristic yellow color through selective light absorption. The metal absorbs blue and violet wavelengths (400-500 nanometers) while reflecting yellow, orange, and red wavelengths (550-750 nanometers). At 0.1 micrometer thickness, gold leaf transmits approximately 30-40% of incident light, with transmitted light appearing greenish-blue (the complementary color to reflected yellow). This semi-transparency explains why bole color profoundly influences the final appearance: light passes through the gold, reflects from the bole, and returns through the gold, with the bole color mixing optically with the gold’s inherent yellow.

The refractive index of gold (n = 0.47 for yellow light) combined with its high extinction coefficient produces strong surface reflectivity. Burnished water gilding exploits this by creating atomically smooth surfaces that produce specular (mirror-like) reflection, while unburnished surfaces scatter light diffusely through microscopic surface irregularities. This optical difference creates the dramatic contrast characteristic of fine water gilding.

Conservation and Longevity Data

Documented examples of historical gilding provide empirical data on durability. The Golden Pavilion in Kyoto, Japan, originally gilded in 1397 and reconstructed in 1955, employs 23-karat gold leaf over traditional Japanese lacquer preparations. Exterior surfaces require re-gilding every 20-30 years as environmental exposure gradually erodes the gold layer through wind abrasion, acid rain, and ultraviolet degradation of underlying organic materials.

Interior water gilding demonstrates exceptional permanence when properly maintained. Renaissance panel paintings in museum collections retain original burnished gilding after 500+ years, with losses primarily due to mechanical damage rather than material degradation. The protein glues in gesso and bole remain stable in controlled environments (40-60% relative humidity, 18-22°C), though they become brittle and susceptible to cracking under severe humidity fluctuations.

Oil gilding on architectural elements shows variable longevity depending on gold purity and exposure severity. Cathedral domes gilded with 23.75-karat double-weight gold in temperate climates maintain an acceptable appearance for 30-40 years before re-gilding becomes necessary, primarily due to accumulated dirt and atmospheric particulate deposition rather than gold degradation. Industrial environments with high sulfur dioxide concentrations accelerate deterioration, requiring more frequent maintenance cycles.

Modern Applications and Technical Innovations

Contemporary gilding extends beyond traditional frames and furniture into architectural restoration, liturgical art, decorative glass, and luxury automotive detailing. The fundamental techniques remain unchanged from historical practice, but material refinements improve consistency and working properties. Pre-prepared rabbit-skin glue in granular form eliminates the need to prepare parchment clippings. Standardized bole colors ensure reproducible results across projects, though some practitioners maintain that historical cone boles had superior burnishing characteristics due to natural variations in clay minerals.

Transfer gold leaf mounted on tissue paper enables outdoor application in conditions where loose leaf would be unmanageable, though the tissue texture can transfer slight surface irregularities to the finished gilding. A patent (transfer) leaf typically costs 20-30% more than a loose leaf due to the additional manufacturing step, but this premium is justified for in-situ architectural work where scaffolding time is the dominant cost component.

Thickness Specifications Across Manufacturing Sources

| Manufacturer Region | Standard Weight (g/1000 leaves) | Double Weight (g/1000 leaves) | Thickness (micrometers) |

|---|---|---|---|

| Northern Europe | 1.25 | 1.4-1.6 | 0.10-0.125 |

| Russia | 1.4 | 2.5 | 0.12-0.20 |

| China | 1.15-1.3 | 1.5 | 0.09-0.13 |

| Japan | 1.2 | Not standard | 0.10 |

Technical Failures and Diagnostic Indicators

Gilding defects arise from preparation errors, material incompatibilities, or environmental factors. Bubbling in gesso layers indicates excessive heat during application, inadequate drying between layers, or overly strong glue concentrations that create internal stresses during curing. Pinholes result from air entrapment or contamination with dust particles. The characteristic appearance of pinhole failures permits diagnosis: randomly distributed holes suggest airborne contamination, while pinholes along carved edges indicate inadequate wetting of vertical surfaces during gesso application.

Gold leaf faulting (gaps in coverage) on water gilding typically originates from insufficient size water application, over-absorption by improperly sealed bole, or delayed leaf application after size water has dried. Oil gilding faults manifest differently: the gold appears to bridge over surface irregularities rather than conforming to contours, due to an over-tack mordant that has progressed too far in its polymerization cycle.

Delamination of entire gilded sections indicates fundamental adhesion failure between preparation layers. Water gilding delamination most commonly occurs at the wood-gesso interface from inadequate initial sizing or subsequent moisture infiltration that swells the wood grain. Oil gilding delamination typically originates from contaminated surfaces during preparation, particularly residual oils or silicones that prevent mordant adhesion.

Conclusion

The dichotomy between water- and oil-gilding represents fundamentally different approaches to achieving permanent gold decoration, each optimized for specific applications and performance requirements. Water gilding delivers unmatched visual quality through burnishing capability but demands porous substrates and controlled environments. Oil gilding sacrifices burnish potential for substrate versatility and weather resistance, enabling applications that are impossible with traditional water-based methods.

Material science explains gold’s enduring dominance: no synthetic coating or imitation metal replicates its permanent stability, optical properties, and workability. The metal’s atomic structure permits reduction to sheets measuring 400 times thinner than human hair while maintaining mechanical integrity – a feat unmatched by any other material. This unique combination of malleability, inertness, and reflectivity ensures that gold leaf gilding remains the definitive method for creating permanent decorative metallic surfaces, continuing techniques documented in Egyptian hieroglyphics and validated by modern conservation science.